Designed primarily for medium capacity (565 Nm – 5,650 Nm) torsion testing of materials and components, the MT torsion systems offer accurate, multi-turn capability, and high-rotational stiffness. The system torque cell is attached to a movable crosshead, which can be positioned at any location along the linear slide. Closed-loop servo-control of the electromechanical drive is provided by Instron’s 5900 Control Electronics and Bluehill® Universal software.

Features

- Dual linear slide design provides high rotational stiffness

- Adjustable crosshead system allows for easy positioning anywhere along linear slide

- Interlocked chuck guard enhances operator safety

- Digital control electronics allow for accurate and repeatable test results and fast control response for both torque and angle

- Torsion testing software offers easy test set up, graphical data plots, automatic calculation of desired test results, and flexible reporting tools

- Large tabletop design

Models

MT5

- Maximum Torque Capacity: 565 Nm (5,000 lbf – in)

- Maximum Test Speed: 18 RPM

MT10

- Maximum Torque Capacity: 1,130 Nm (10,000 lbf – in)

- Maximum Test Speed: 9 RPM

MT20

- Maximum Torque Capacity: 2,260 Nm (20,000 lbf – in)

- Maximum Torque Speed: 4.5 RPM

MT50

- Maximum Torque Capacity: 5,650 Nm (50,000 lbf – in)

- Maximum Torque Speed: 1.5 RPM

Typical Applications

- Metals

- Wire Rod

- Tools

- Fasteners

- Automotive Components

axial loads. Servo torque motor, servo hydraulic linear actuators, customized fixtures, and transducers simulate the real test conditions with a computerized (2360) controller. The system meets JASO C 715, SAE J 193 and SAE J 1367.

Testing Applications

- Oscillation angle test

- Torque test

- Rigidity test

- Extrusion and drawing strength test

- Ball stud static strength test

- Fatigue strength test

- Service temperature abrasive durability test

- Muddy water durability test

- Dust cover Ozone deterioration, low temperature and heat resistance test

- Optional testing under cold temperatures up to -400C

- Optional testing under hot temperatures up to 2000C

Features & Benefits

- Two 50 kN (11,250 lbf), ± 150 mm (6 in) linear actuatiors

- 5,000 Nm (44,250 lbf∙in) servohydraulic rotary actuator

- Suitable for static and dynamic testing

- 2360 digital controller for synchronous multi-axis control and data acquisition

- “Green” highly efficient hydraulic power pack

- Optional envrionmental chambers and muddy water system

- 12 month warranty and customer support services

- Meets or exceeds nation and international accuracy standards for materials testing system

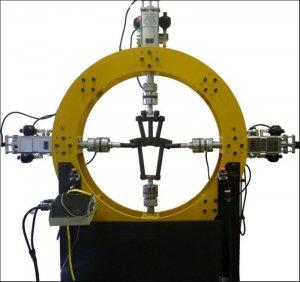

974 Series servohydraulic planar biaxial test system enables static, dynamic, and fatigue tests on high strength square, rectangular and cruciform test samples. 974 systems are used for metal and composite fatigue and fracture and configured for higher forces and test speeds compared to the electrodynamic 574 series. They feature higher force capacities and higher speed capabilities compared to the 174 series.

Transducers include load and position encoder based measurements with both contacting and non contacting strain based extensometers available. The video extensometer is based on digital image correlation (DIC) technology. The mechanical extensometer is a two channel wheatstone bridge.

This system features high precision load and optional strain control on two synchronized axes which makes it possible to create controlled complex biaxial stress and strain test states. The system is programmed for tensile and tension-tension fatigue tests on flat test samples. Our four channel controller controls all four actuators independently to move in opposite directions on two axis perpendicular to each other.

Each system features four individually controlled servohydraulic actuators programmed to create synchronized yet independent control load and strain. They generate high precision states of stress along two axis (XY plane) in a biaxial mode. Tension, compression, and shear tests can be performed at a constant speed, constant load rate static tests, high speed, and high frequency load controlled fatigue tests. The actuator force rating, test stroke and operating frequencies are made to order and designed to match application requirements.

Features

- Test Space designed for customer samples and applications

- Four channels of independent load, position and strain control

- Actuator strokes to 100 mm (4 in)

- 5,000 Hz data acquisition rate

- Wide range of compatible optional accessories including tensile grips, compression and bend fixtures, environmental chambers, extensometers, etc.

- 12 month warranty and customer support services

Options

- Actuator stroke made to application requirements

- Strain measurement and control

- Integrated standalone video extensometer with DIC technology

- Accessories to match application – grips, fixtures, chambers

System Specifications

| Model | Max Force Capacity |

| 974L50 | 50 kN (11,250 lbf) |

| 974L100 | 100 kN (22,500 lbf) |

| 974L250 | 250 kN (55,000 lbf) |

| 974L500 | 500 kN (110,000 lbf) |

| 974L2000 | 2 MN (450 kip) |

Applications

High strength materials such as steel, aluminum, laminated composites, polymer reinforced composites, concrete and concrete reinforcements. Test types including fatigue, static and fracture tests such as fatigue crack growth.

Accessories

Each system includes sample grips or test fixtures, strain measurement and strain control options, chambers and bathes to produce a controlled test media. We are experts at supplying turnkey systems with integrated fixturing and strain measurement instrumentation.

- Environmental Chambers & Solutions

- Extensometers

- Contacting

- Non contacting video

- Grips and Fixtures compatible with environments